How Does Reaction Injection Molding Work?

Is Reaction Injection Molding a Fit For Your Needs?

Advantages

-

Strong Yet Light Parts

RIM produces parts that are light weight but still maintain high strength and rigidity thanks to the thermoset polymers used. This makes it ideal for automotive, aerospace and equipment housings where weight reduction is crucial but you can’t compromise on durability.

-

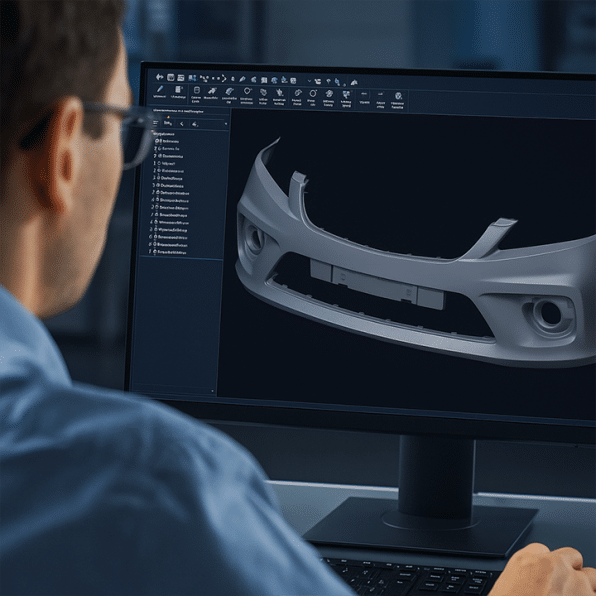

Design Flexibility

RIM supports complex geometries, varying wall thicknesses and intricate features. Multiple components can be integrated into a single molded piece, providing substantial cost savings on assembly.

-

Material Versatility

A wide range of polymer mixtures can be used to achieve different mechanical properties. Simply modify the ratios of them to adjust flexibility, impact resistance or thermal stability.

-

Lower Tooling Costs

RIM operates under low injection pressures, which enables the use of less expensive tooling materials such as aluminum. This significantly reduces the upfront tooling investment compared to injection molding.

-

Low Residual Stress

Forming parts at low pressures and temperatures minimizes internal stresses. This reduces warping and cracking and improves long-term stability.

-

Cost-Effective For Thick/Large Parts

RIM is a good match for production of medium to large components because it avoids the high pressures and heavy machinery associated with traditional molding. It also can produce thick cross-sections without sink marks or voids, which results in strong components with consistent density and performance.

-

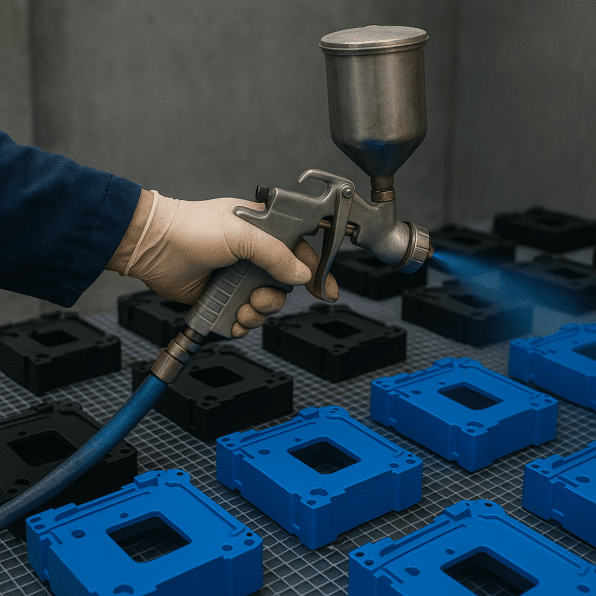

Finished Surfaces

Finished parts can have smooth surfaces suitable for painting or coating, minimizing the need for post-processing. Parts also can emerge at the desired color for visually appealing, production-ready components straight out of the mold.

Disadvantages

-

Longer Cycle Times

RIM generally has slower curing and demolding times when compared to injection molding. This can limit production speed and make RIM impractical for high-volume manufacturing.

-

Limited Material Options

RIM primarily uses thermosetting polyurethanes, which restrict the range of materials compared to conventional injection molding. Certain applications requiring other plastics, metals or high-temperature polymers may not be a good fit for RIM.

-

Tolerance Challenges

Material shrinkage during curing can reduce part precision. Components with extremely tight tolerances may require secondary machining or finishing.