How Water Jet Cutting Works

Advantages of Water Jet Cutting

Advantages

-

Material Versatility

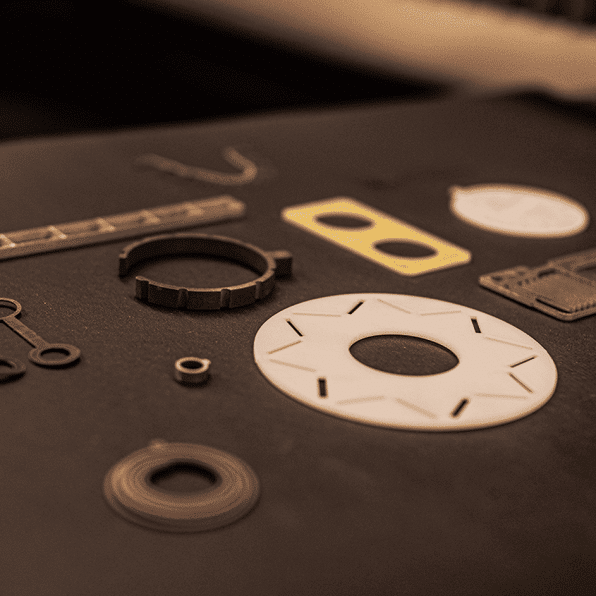

Water jetting cuts virtually any material: From metal and stone to composites and even food, water jet cutting is extremely versatile. It can also cut bonded and laminated materials.

-

Complex Shapes & 3D Cutting

This technology can handle intricate designs and, with 5-axis cutting heads, can produce beveled edges and 3D shapes.

-

No Heat-Affected Zones

Water jet cutting doesn’t generate heat, which prevents damage from warping, distorting or hardening the material’s edge.

-

Can Cut Thick Materials

Water jets can cut through very thick materials, sometimes exceeding 10 inches, while maintaining accuracy.

-

Cost-Effective

Water jet cutting is efficient because of its fast setup and programming and by nesting parts closer together, it minimizes material waste

Disadvantages

-

Reduced Accuracy with Thick Materials

As material thickness increases, the cutting jet stream can spread and become less accurate, causing a diagonal cut rather than a straight one.

-

Slower Cutting Speed

Compared to other cutting methods, water jet cutting is often slower, which reduces output.

-

Inner Corner Radius Can’t be Eliminated

Water jets cannot create perfectly sharp inside corners and will leave a small radius equal to the width of the jet stream.