How

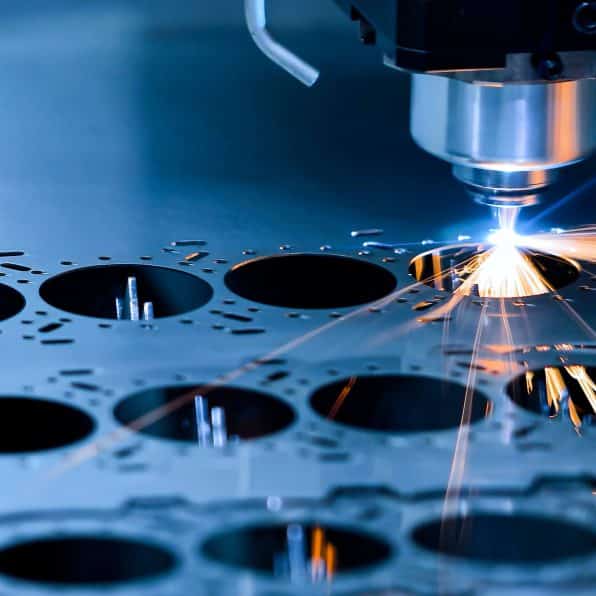

Advantages & Disadvantages of Laser Cutting

Advantages

-

Affordability

High speed and high quality make industrial laser cutting very cost-competitive and a real value for our customers. It’s an ideal process for prototype to low-volume production quantities of laser cut parts.

-

Automation

Laser cutters at our Denver facility are equipped with automatic loading and unloading systems, enabling us to process large orders on a lights-out basis. That helps us keep our costs competitive and helps us deliver your finished parts faster.

-

Precision Details

Laser cutting can produce small, precise holes and fine details in sheet metal.

-

Tight Tolerances

CNC controls maintain critical tolerances while accommodating fine features and larger blank sizes.

-

Quick Turn-Around

Laser cutting jobs can be set up and running quickly – perfect for fast turnarounds on small batches of parts. Because laser cutting doesn’t apply any physical forces to the sheet metal, it doesn’t need to be held in place with jigs or work-holding fixtures. That speeds up the setup and production times.

-

Little or No Finishing Required

Industrial laser cutting produces high-quality edge finishes that require little or no post-processing. Some cleanup of burn marks may be required.

-

Maximize Material Use

Multiple parts can be cut from the same sheet. That helps to minimize waste.

Disadvantages

-

Heat-Affected Zones

Because laser cutting generates heat, it can alter the chemical and structural characteristics of the metal near the cutting edge – called “heat-affected zones” (HAZ). Effects may include oxidation, brittleness and corrosion. However, laser cutting generates smaller heat-affected zones than other thermal cutting techniques.

-

Material Limitations

Laser cutting can’t cut through thicker sheet metal. Water jet cutting works better for thick materials.