How Does Large Format Sheet Metal Fabrication Work?

Advantages & Disadvantages of Large Sheet Metal Fabrication

Advantages

-

Customization

Because sheet metal is easy to work with, we can build custom metal parts that meet your precise requirements.

-

Affordable

Compared to machining, sheet metal fabrication is much less expensive and provides flexibility during each step of the fabrication process.

-

Accurate

Metal parts are cut to precise sizes and shapes using computer-controlled equipment. This minimizes the need for secondary processes such as grinding and polishing.

-

Scalability

Sheet metal forming accommodates production changes without big investments in retooling. This makes it well-suited for creating prototypes and small batches of parts for testing and validation. It’s also a cost-effective way to produce production parts in small to medium-sized quantities.

-

Short Lead Times

Sheet metal fabrication doesn’t require many processing steps. That’s why its lead time is often shorter than other manufacturing technologies. This makes it a popular option for sheet metal prototyping.

-

Aesthetic Appeal

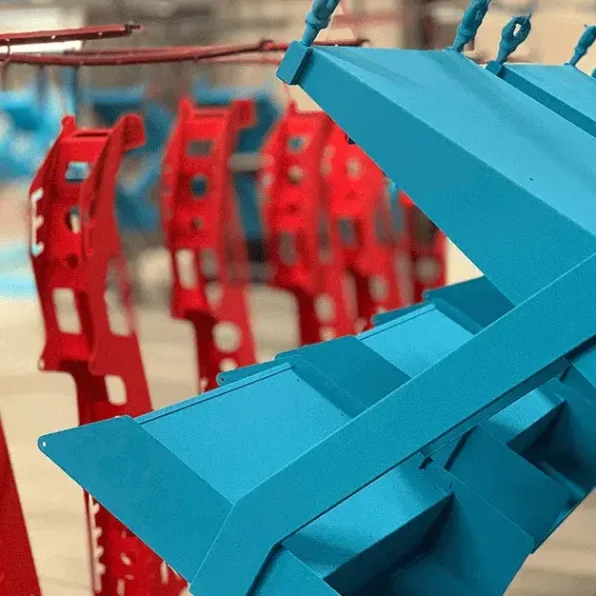

Sheet metal offers multiple finishing options that we use to enhance its appearance and protect it from corrosion. They include painting, powder coating and anodizing.

Disadvantages

-

Overhead Costs

Many metals require additional finishing processes, such as deburring or painting after fabrication. That can increase production time and overhead costs.

-

Design Limitations

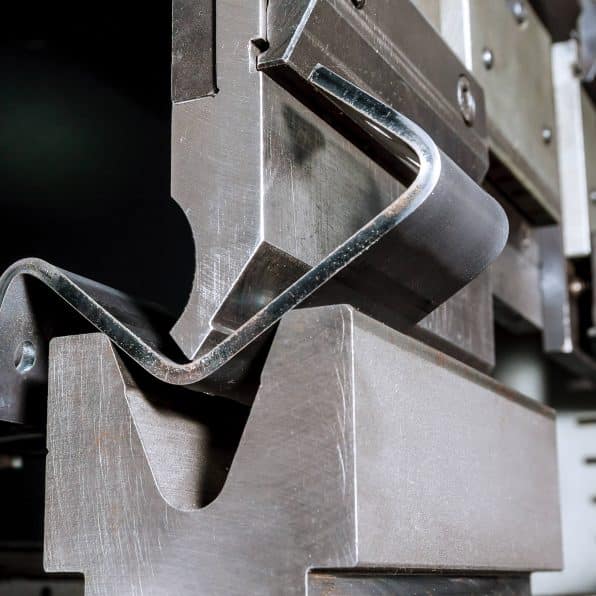

Sheet metal must have a uniform material thickness. Corners are created by bending metal. That’s why they must have minimum radii equal to the material thickness. Some bends may require relief notches to prevent unwanted deformation. Holes and tabs can’t be located too close to bends. Otherwise, bulges may occur. And there are some limitations on where you can locate welds to hold parts together.