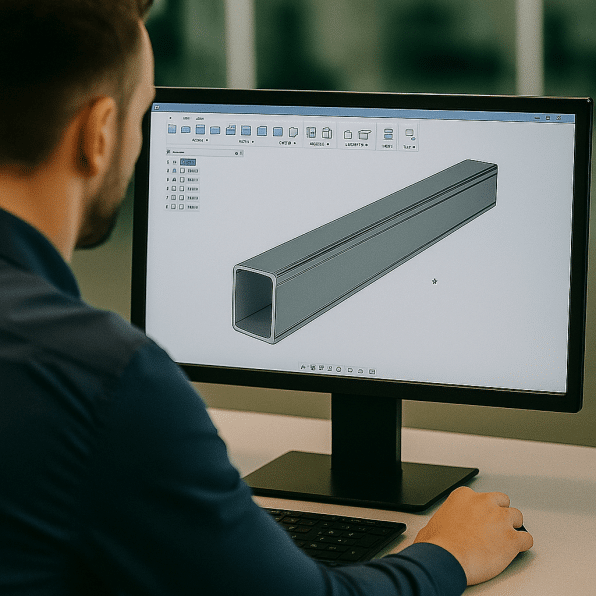

How Does Plastic Extrusion Work?

Is Plastic Extrusion A Fit For Your Needs?

Advantages

-

Cost-Effective

The continuous plastic extrusion process combines high production efficiency with minimal material waste. It is a cost-effective choice for large-scale manufacturing runs.

-

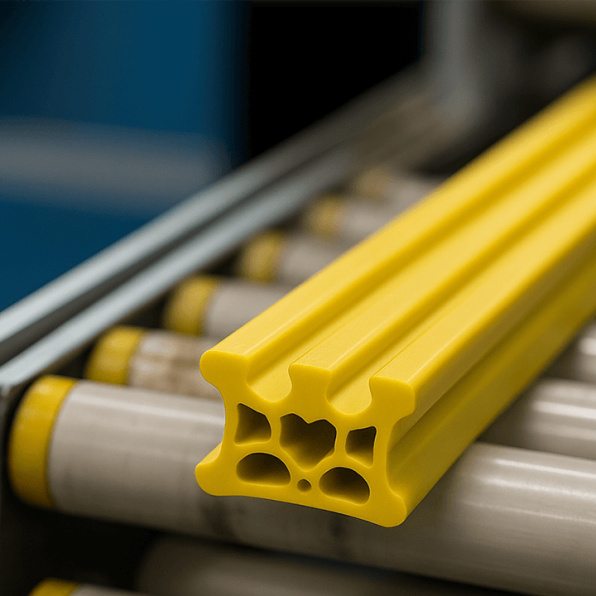

Consistent Quality

Plastic extrusion lends itself to consistency – especially uniform material flow and proper sizing. This results in smooth surface finishes and high quality across long production runs.

-

Flexibility

Custom-designed dies enable the production of complex cross-sections. This helps manufacturers meet specific design and application requirements.

-

Versatile Materials

A wide variety of thermoplastics can be used – with each offering different properties such as strength, flexibility or UV resistance. Products therefore can be tailored to a variety of applications, both indoor and outdoor.

Disadvantages

-

Initial Costs

Creating custom dies and tooling involves significant upfront investment. This makes plastic extrusion impractical for prototyping or short production runs.

-

Limited Shapes

Extrusion is best suited for parts with uniform cross-sections. Complex or irregular shapes with varying profiles are better suited to molding or machining methods.

-

Shrinking and Swelling

Plastic materials can expand when leaving the die – and contract during cooling. Achieving extremely tight tolerances can be challenging.