How Does Metal Extrusion Work?

Is Metal Extrusion a Fit for Your Business?

Advantages

-

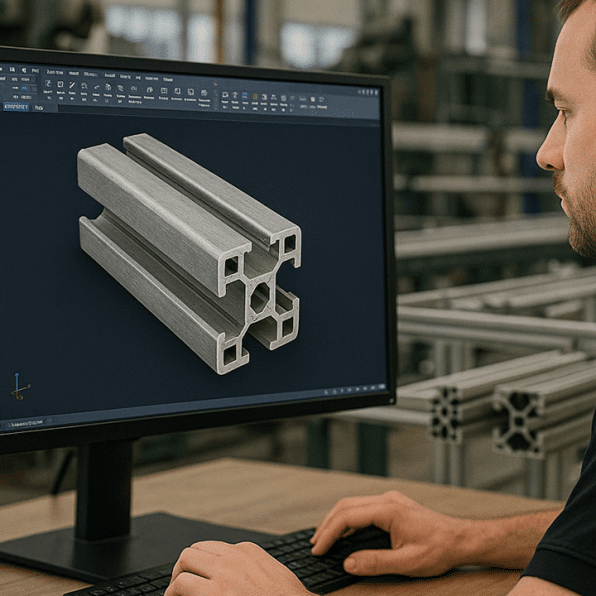

Complex, Uniform Shapes

Metal extrusion can create long parts with intricate cross-sections that would be difficult or impossible to machine. The consistent flow of material through the die ensures the shape remains constant.

-

Reduced Waste

Most of the billet material becomes part of the final product, reducing scrap and improving cost efficiency. Savings can be substantial on high-volume projects.

-

High-Quality Finishes

The pressure and controlled metal flow results in smooth surfaces and precise dimensions. This often reduces or eliminates the need for additional finishing.

-

Improved Mechanical Properties

Aligning the metal’s grain structure with the direction of the extrusion increases strength. This directional grain flow is essential in structural and load-bearing applications.

-

Varied Materials and Shapes

A wide range of metals can be utilized, including aluminum, copper, steel and magnesium alloys. Extrusion can produce everything from simple rods and tubes to highly complex profiles.

-

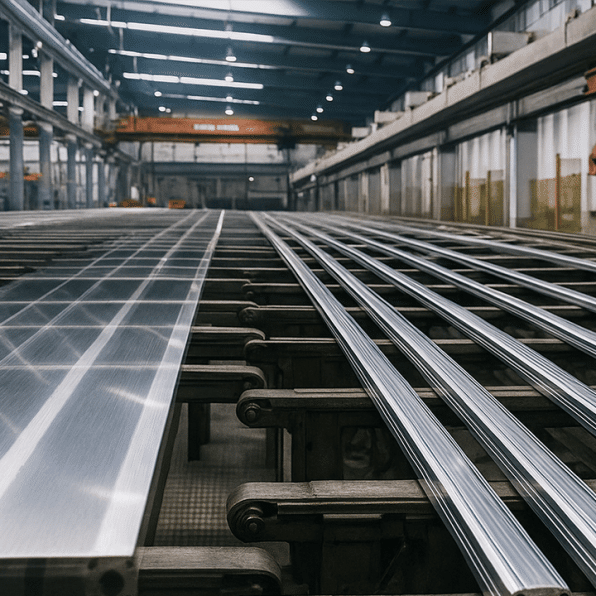

Ready for High Volumes

Extrusion is well-suited for continuous manufacturing, allowing long lengths of product to be produced in a single run. This efficiency reduces production time and improves consistency, making it ideal for high-volume applications.

Disadvantages

-

High Initial Costs

Designing and creating metal extrusion dies can be expensive. This makes it impractical for small production runs and prototype work.

-

Careful Monitoring

Excessive friction or uneven heating can cause surface defects, tearing or dimensional inaccuracies. Careful monitoring of processes and lubrication are essential for consistent extrusion quality.

-

Material Limitations

Not all metals are equally suitable for extrusion. Some high-strength alloys are difficult to process and may require higher pressures, specialized equipment or alternative forming methods.