How Does Vacuum Die Casting Work?

Is Vacuum Die Casting a Fit For Your Needs?

Advantages

-

Reduced Porosity

VDC removes air and gases from the die cavity before metal injection, which significantly reduces porosity in the casting. It also prevents air entrapment, which can cause weak spots in castings. VDC results in stronger, more reliable parts with improved structural integrity.

-

Improved Surface Finish

This vacuum-assisted casting process minimizes defects such as gas pockets and surface blemishes. The casting often requires less post-processing to achieve a smooth, high-quality surface.

-

Enhanced Mechanical Properties

By reducing trapped gases and impurities, VDC produces denser metal with better tensile and fatigue strength. This makes the parts suitable for demanding applications like automotive and aerospace components.

-

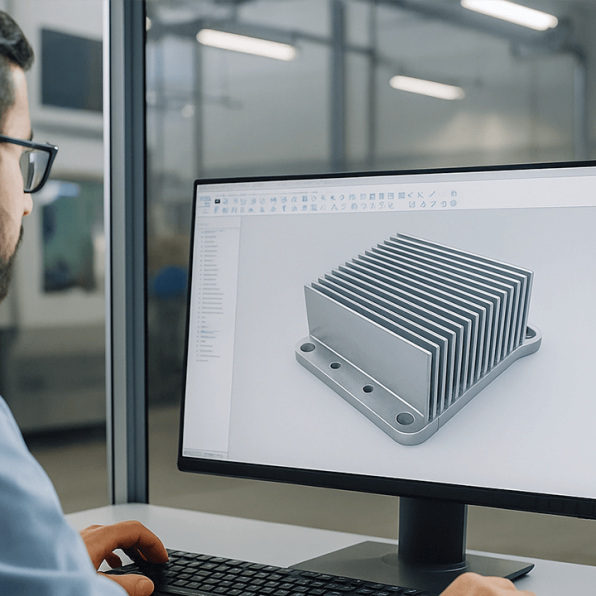

Precision & Accuracy

Vacuum die casting allows for tighter dimensional tolerances and consistent reproduction of complex geometries. This reduces the need for extensive machining or corrective work after casting.

-

Reduced Shrinkage & Defects

The controlled metal flow under vacuum conditions helps prevent shrinkage, voids and other internal defects. This increases the yield of usable parts and reduces material waste.

Disadvantages

-

Higher Equipment Costs

Vacuum die casting requires specialized dies, vacuum systems and pumps that increase initial investment costs. This can make it less economical for small production runs compared to conventional casting methods.

-

Complex Maintenance

The vacuum system, valves and seals require careful maintenance to ensure consistent performance. Any leakage or failure can compromise the quality of the castings and cause production delays.

-

Limited Material Options

VDC is primarily used for non-ferrous metals like aluminum, magnesium and zinc. Ferrous metals, such as steel, are difficult to process due to their higher melting temperatures and adverse reaction to vacuum conditions.