How Does Low-Pressure Die Casting Work?

Is Low-Pressure Die Casting a Fit for Your Needs?

Advantages

-

Improved Metal Flow and Porosity

LPDC ensures even metal flow, which reduces turbulence and minimizes trapped air. The result: few porosities and stronger, more reliable castings compared to high-pressure die casting.

-

Better Mechanical Properties

Parts produced under low pressure generally have higher density and fewer internal defects. This improves tensile strength, fatigue resistance and overall durability compared to high-pressure die casting.

-

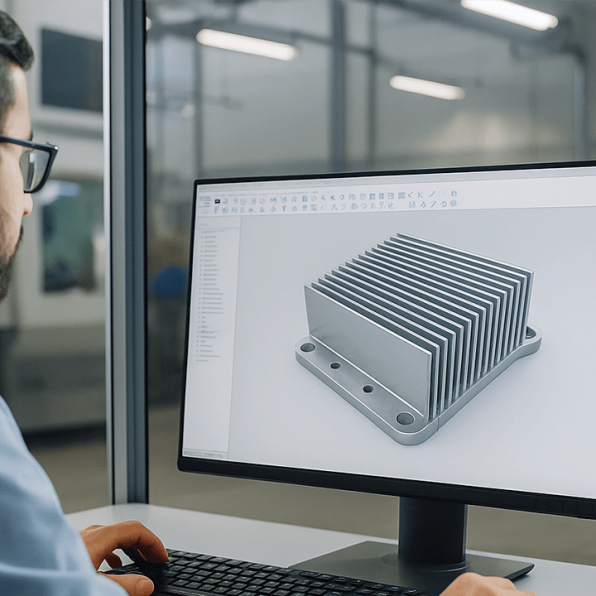

Dimensional Accuracy

The controlled flow enables precise filling of intricate mold features. This reduces the need for extensive machining or post-processing.

-

Reduced Material Waste

Overflow is minimal because the metal is pushed gradually into the mold. This conserves expensive alloys and keeps scrap rates low.

-

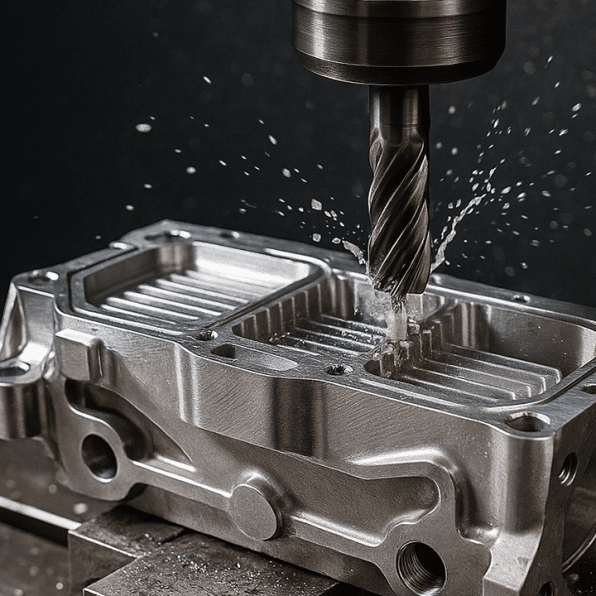

Thin Walls & Complex Shapes

LPDC excels at producing parts with thin sections that are difficult to achieve through gravity casting. Complex geometries can be formed without compromising structural integrity.

Disadvantages

-

High Initial Costs

LPDC requires specialized furnaces, pumps and molds. The initial investment is significantly higher compared to gravity casting or other simpler methods.

-

Slower Production Rate

Filling the mold under low pressure is slower than high-pressure die casting. This can limit production speed, especially for large part orders.

-

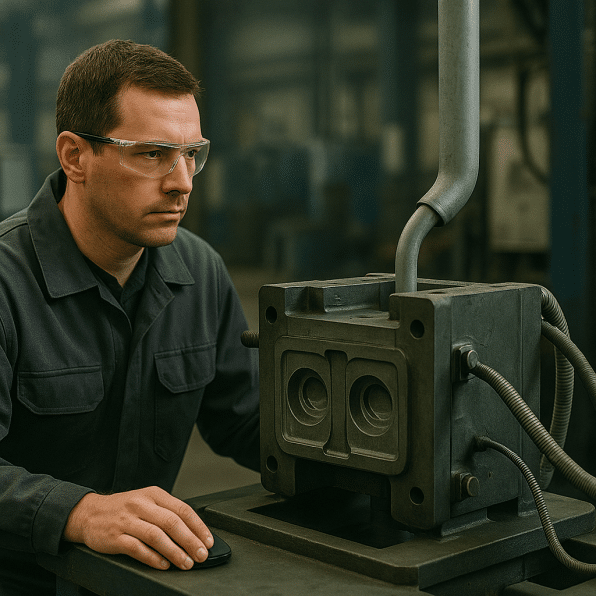

Complex Process Control

Operators must precisely control temperature, pressure and timing. Even small deviations can lead to defects such as cold shuts or incomplete filling.