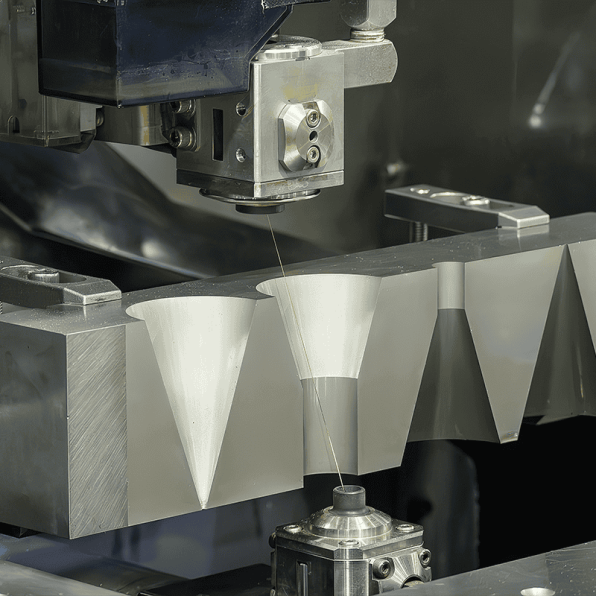

How Plunge EDM Cutting Works

What Are the Pros & Cons of Plunge EDM Cutting?

Advantages

-

High Precision & Accuracy

Plunge EDM is capable of drilling very small and precise holes, often down to a few microns in diameter.

-

Material Versatility

It efficiently drills through extremely hard materials like hardened steel, tungsten carbide and superalloys, which are difficult for conventional methods.

-

Complex Geometries

Plunge EDM can produce holes on curved or angled surfaces and create deep holes with high aspect ratios that are challenging for traditional drills.

-

Non-Contact Process

The plunge EDM process creates burr-free holes and leaves no physical stress on the workpiece. Plunge EDM is not limited by material hardness or brittleness. It’s ideal for high-mix, low-volume production projects. Electrodes are easy to manufacture, because they don’t need to be harder than the material they are going to cut.

Disadvantages

-

Limited to Conductive Materials

The plunge EDM drilling process can only machine electrically conductive materials like metals and certain alloys, not plastics or composites.

-

Slow Process

Plunge EDM drilling can take several minutes per hole, making it unsuitable for high-volume production

-

Electrode Wear

The electrode wears down during the process, which can be significant and may require replacement or maintenance.

-

High Cost

Both the initial setup and operating costs can be higher than conventional drilling due to specialized equipment, energy consumption and labor time.