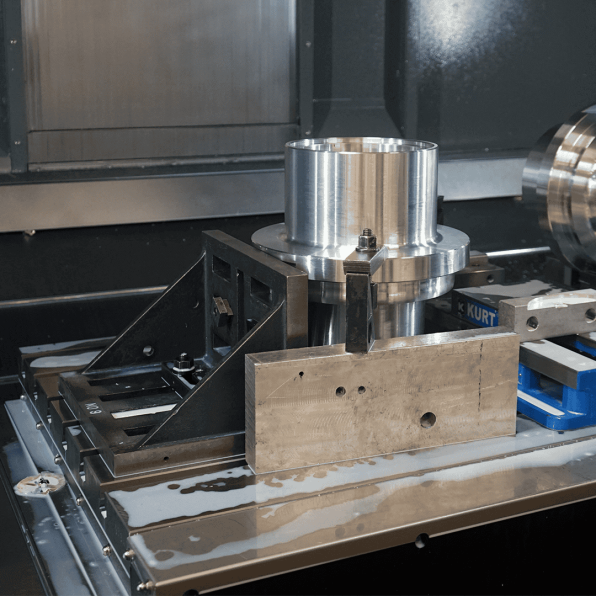

How CNC Turning Works

Is CNC Turning Right For Your Project?

Advantages

-

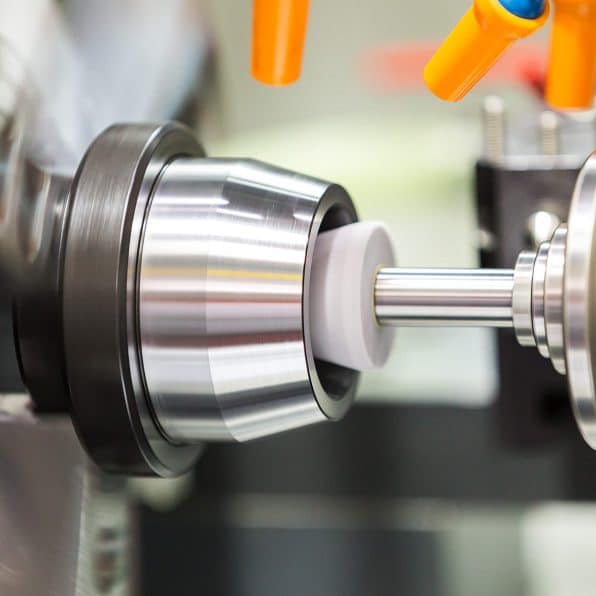

Precision & Accuracy

CNC turning can achieve extremely tight tolerances and produce parts with very high dimensional accuracy.

-

Consistency & Repeatability

The automated nature of the process ensures that every part produced is identical, which is crucial for mass production and consistent quality.

-

Reduced Waste & Lower Costs

The exceptional accuracy of CNC turning translates into reduced rework and waste, which helps to reduce per-part costs.

-

Versatility

CNC lathes can work with a wide variety of materials, including metals, plastics, and composites, allowing for a wide range of applications.

-

Excellent Surface Finish

CNC turning can produce parts with high-quality surface finishes, which is important for many industrial applications.

Disadvantages

-

Only Cylindrical Patrs

CNC turning is restricted to creating cylindrical and rotational-symmetry components, limiting its use for more complex shapes.Also, certain features and geometries cannot be machined using this method. Examples include curved holes, extremely thin walls and straight internal edges,

-

Production Limitations

While precise for single units, the process of producing one unit at a time can make it slow for large batches compared to other methods.

-

Skilled Operators Required

Skilled operators and programmers are required to setup, maintain and troubleshoot CNC turning machines. Mistakes in CAD/CAM programming can cause costly errors or downtime.