How 5-Axis CNC Machining Works

Is 5-Axis Machining Right For Your Project?

Advantages

-

Complex Shapes

5-axis machining can produce intricate designs with curves and angles that are difficult or impossible on 3-axis machines.

-

Increased Accuracy

It can machine multiple sides of a part in a single setup, eliminating the need to reposition the workpiece. This reduces errors and leads to higher precision and tighter tolerances.

-

Reduced Setup Time

By machining multiple faces in a single setup, 5-axis machines significantly cut down on the time and cost associated with multiple setups and fixtures.

-

Improved Production

The ability to machine more complex parts and use shorter tools with higher feed rates leads to faster production times.

-

Better Surface Finish

The cutting tool can maintain a more optimal angle with the workpiece, resulting in a smoother, cleaner cut with fewer tool marks.

Disadvantages

-

Operator Skill Level

Operating these machines requires a higher level of skill, including advanced 3D visualization and a thorough understanding of multi-axis motion to avoid collisions and ensure accuracy.

-

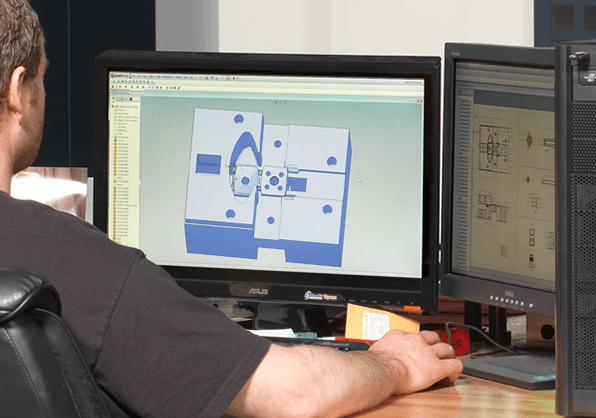

Complex Programming

Creating accurate and efficient tool paths is more complex and requires sophisticated CAM software and a deep understanding of 5-axis principles.

-

Setup Time

Setup and programming can take more time compared to simpler 3-axis machines.

-

Accuracy

Maintaining high position accuracy can be more challenging due to factors like heat generation, mechanical transmission errors, and angular errors in the rotational movements.