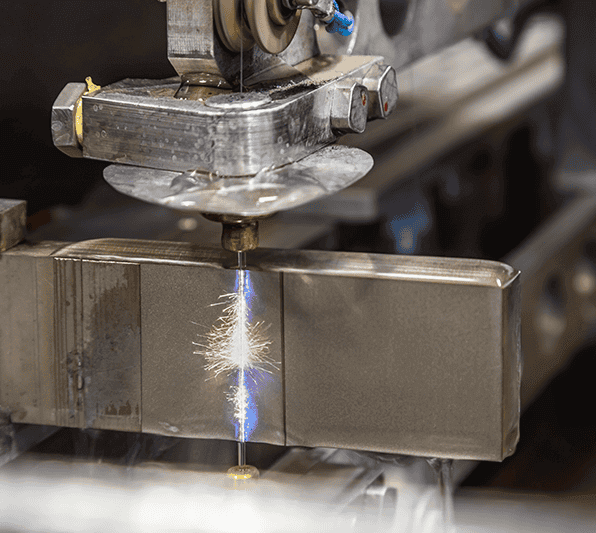

How Wire EDM Cutting Works

What Are the Pros & Cons of Wire EDM Cutting?

Advantages

-

Precision & Accuracy

Wire EDM machining makes precise and accurate cuts, often within ±0.0002 inches, and cut intricate details with high accuracy.

-

Tight Corners

Wire EDM cutting can create extremely tight corner radii, which is difficult with conventional machining methods. This capability is ideal for fabricating injection mold tools.

-

Ideal for Cutting Tough Materials

Wire EDM can cut extremely hard, strong, and difficult-to-machine conductive materials that are challenging for traditional machining, such as Inconel, titanium and superalloys.

-

Efficient for Cutting Brittle Metals

The lack of mechanical contact between the wire and the workpiece means delicate or weak parts can be machined without distortion.

-

Cost Effective

Wire EDM cutting is surprisingly efficient: Metal plates can be stacked to cut multiple workpieces in a single pass.

Disadvantages

-

Conductivity Requirement

Wire EDM can only machine electrically conductive materials, such as metals. It cannot cut non-conductive materials like most plastics, ceramics, or composites.

-

Slow Cutting Speed

Wire EDM cutting is significantly slower than conventional machining, water jet cutting, or laser cutting, making it less efficient for simple or high-volume jobs.

-

Heat-Affected Edges

A thin layer of oxide or recast material can form along the cut edge, which may need to be removed with a secondary process like electropolishing

-

Skilled Operator Required

Wire EDM requires significant operator expertise to set up and run correctly.