How Does SLS Work?

Is SLS Right For Your Project?

Advantages

-

Proven Technology

Of all the 3D printing technologies, SLS is one of the most mature and widely used. It has a strong track record of success as a rapid prototyping and production tool. SLS parts have an excellent reputation in many diverse applications.

-

Complex Geometries

SLS can print complex and intricate parts with fine details. That makes it well-suited for producing functional prototypes and end-use parts with unique shapes.

-

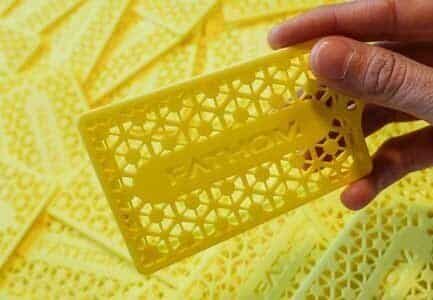

Produce a Large Volume of Parts Quickly

Multiple parts can be produced at the same time in a single build. The laser used during SLS has a quick scanning speed. That means high throughput at a low cost per part.

-

Low Cost Per Part

Leftover powder can be reused and support structures are not needed. Also, post-processing is less labor intensive than with other 3D printing methods. That makes SLS parts very affordable.

-

Design Flexibility

This industrial 3D printing process enables you to build parts with complex geometries, moving parts and pieces with interior components. That’s because it doesn’t require support structures.

-

Superior Mechanical Properties

Because of the strong bonds between layers, parts produced using SLS tend to have excellent isotropic properties. That means they have similar tensile strength and hardness across all three axes. These characteristics make this commercial 3D printing process an excellent alternative to injection-molded parts.

-

Colorability

SLS parts have porous surfaces. That means they can be enhanced using a variety of colors and dyes.

Disadvantages

-

Surface Quality

Parts produced using SLS tend to have a porous surface and may need to be sanded or coated to achieve the required surface finish. One common treatment Fathom uses on SLS parts is vapor smoothing, which produces a smooth, waterproof surface.

-

Time-Consuming Post-Processing

Depowdering parts after printing can be time-consuming. Parts must be designed with escape holes to enable the removal of powder trapped inside any hollow cavities. SLS parts also require a lengthy cooling process.

-

Shrinkage

SLS parts tend to shrink slightly as they cool. To maintain dimensional accuracy, engineers need to plan for this when designing SLS parts.

-

Warpage

Due to the high heat of the printing process, SLS parts can sometimes warp or deform. That can affect their accuracy and dimensional stability. Your Fathom engineering expert can help you tweak your part designs to minimize or avoid this problem.

-

Limited Material Selection

SLS materials from Fathom are limited to TPU 88A and five types of Nylon.