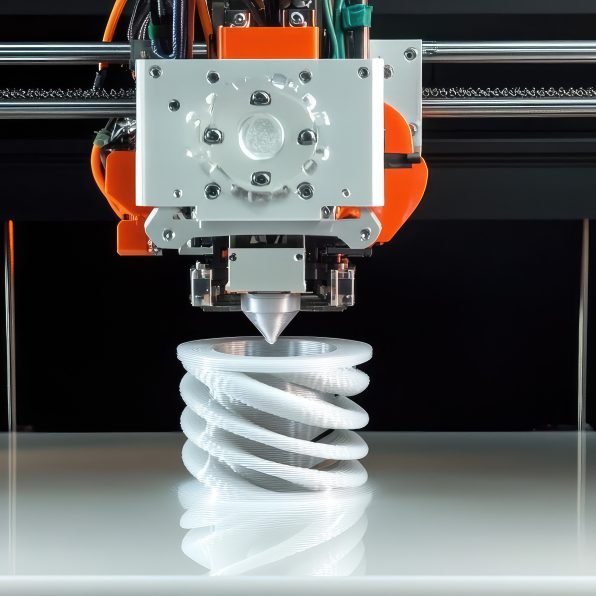

How Does FDM Manufacturing Work?

Advantages & Limitations of FDM

Advantages

-

Printing Speed

FDM machines can print parts faster than many other additive technologies. That means you can get your parts faster.

-

A Wide Range of Materials

Materials for FDM printing include acrylonitrile butadiene styrene (ABS) polymers, polycarbonates, polycaprolactone and polyphenyl sulfones.

-

Exceptional Toughness

FDM parts are rugged and durable. They’re ideal for demanding applications like jigs and work-holding fixtures.

-

The Same Material, From Prototype to Production

Often, when engineers develop prototype part designs, they must settle for a material that only approximates the physical characteristics of the final production part. That’s because they’re unable to use the same material for both manufacturing methods. With FDM, you can print prototype parts using the same materials you’ll be using for your injection molded production parts.

-

Build Functional Prototypes Fast

Your FDM printing service can build functional prototype parts in a few hours or days, depending on the complexity of the design. FDM can help you accelerate your time to market.

-

Support for Low-Volume Production

FDM manufacturing isn’t just for building prototype parts. Thanks to its speed and print quality, you can also use it for low-volume runs of production parts.

-

Variable Infill Density

Like many additive technologies, printing thick part walls with FDM can be challenging. It significantly increases print time and uses a lot of material without increasing wall strength. With FDM additive manufacturing, you can fill these areas with customizable lattice structures. They use less material, reduce print time and provide excellent structural strength. Your FDM 3D printing service can help you decide if variable density infill is a good fit for your part designs.

Disadvantages

-

Anisotropic Characteristics

Because of the way the layers of FDM parts are joined together, they tend to be weaker in the Z direction than other additive technologies.

-

Not Ideal for Small Parts or Details

With a minimum nozzle size of 0.4 inches, FDM isn’t well-suited to print small parts or larger parts with tiny details.

-

Surface Finish

Because the material is extruded in layers, the surface finish of FDM parts may not be as smooth as some 3D printing methods. That means FDM parts may need post-processing to achieve the required surface finish. Be sure to ask your Fathom representative about finishing options for FDM.