Types of Additive Post-Processing

Advantages & Disadvantages of Additive Post-Processing

Advantages

-

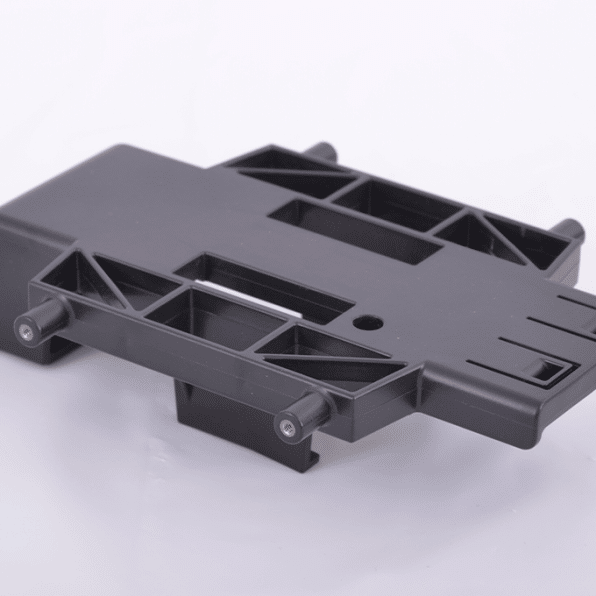

Suitability for End-Use Application

Post-processed parts are more aesthetically pleasing and are ready to withstand the environments in which they will be used.

-

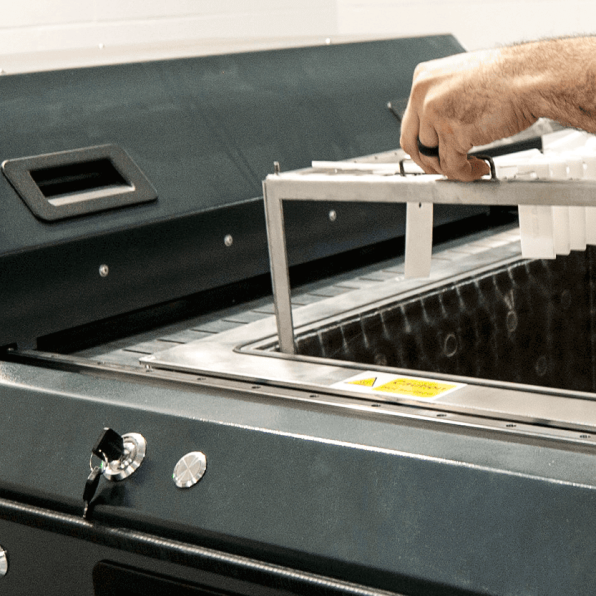

Additive Post-Processing Expertise

You won’t find this level of post-processing craftsmanship anywhere else. We have decades of experience finishing and assembling parts to meet our customers’ strict requirements.

-

Engineering Insights

As part of our DFM process, our experienced engineers can walk you through finishing options to help you select the approach that delivers the best results.

-

Simplify Your Supply Chain

Having us handle these steps in-house saves our customers time and money. Why dedicate precious factory space to finishing your parts when we can do it for you?

-

Speed & Accountability

The same facility that builds your 3D-printed parts also handles the finishing. That means fewer delays (no outsourcing to a third party) and one point of accountability.

-

A Commitment to White Glove Service

Many of our competitors don’t offer post-processing and finishing services. They prefer “print and ship” additive projects. We’re committed to meeting your needs, from design and prototyping to production and post-production.

Disadvantages

-

Adds to Processing Time & Cost

Most additive parts are not ready to use right out of the printer. So when you order them, you need to factor in extra time for post-processing. These extra steps also add to the cost of the parts.

-

You Can’t Skip Post-Processing

Given the current state of additive manufacturing, most parts don’t come off the printer ready to use. They all need some level of post-processing before you can incorporate them into your products.